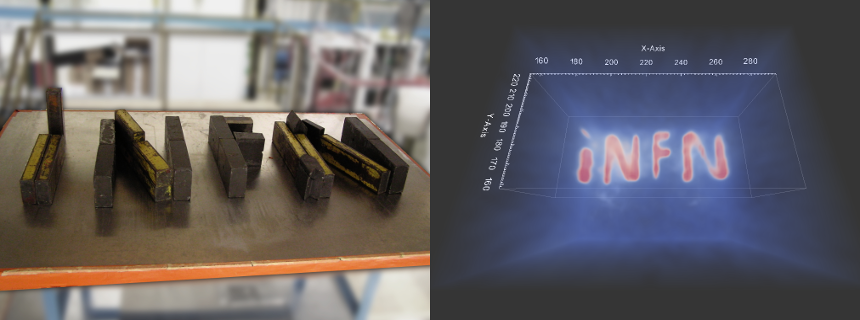

Real Data: Dense Object Reconstruction

We gathered a large amount of data using the LNL prototype (described here). The tomographic reconstruction of the volume enclosed within the muon detectors results as a 3D map that shows the differences in density among the areas. In the Fig. 1 the 3D rendering of the reconstructed density map clearly shows the lead structures composed to write the acronym “INFN”. The identification of high density object in non-accessible volumes (such as trunks, casks, containers) can be crucial when fighting terrorism and smuggling of nuclear and other harmful devices.

Fig. 1 – A lead sample writing the acronym INFN and its muon tomographic reconstruction

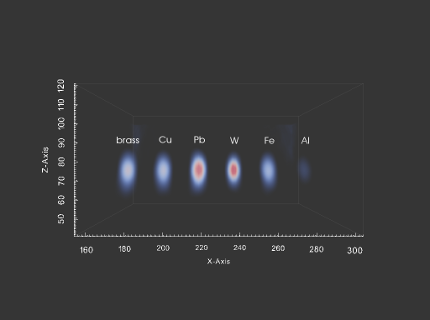

Real Data: Object Density Identification

The step that naturally follows the first reconstruction tests is testing the algorithm capability in building 3D images of different density values for different matierials. If the reconstructed densities will be different, the algorithm can be considered capable of distinguish high density materials from low density ones. In Fig. 2 there is a reconstruction of real data acquired from small blocks of different materials, from Alluminium to Tungsten.

Fig. 2 – Reconstruction of different materials

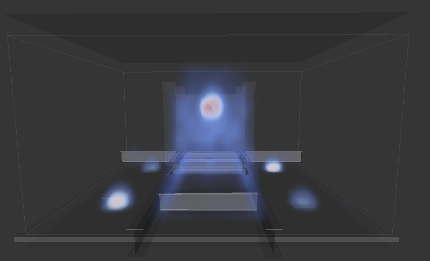

Real Data: Identification of a Lead Block Surrounded by Scrap Metal

The identification process can be hard in presence of other dense material. We propose the reconstruction (Fig. 3) of a basket filled with scrap metal. This application of muon tomography leads to a complementary scanning system for ports and customs. It becomes fundamental when the cargos are lead to metal melting facilities, where an hidden orphan radioactive source can be melted along with the scraps. This kind of accidents quickly turns into a serious environmental damage.

Fig. 3 – Lead block hidden inside scrap metal

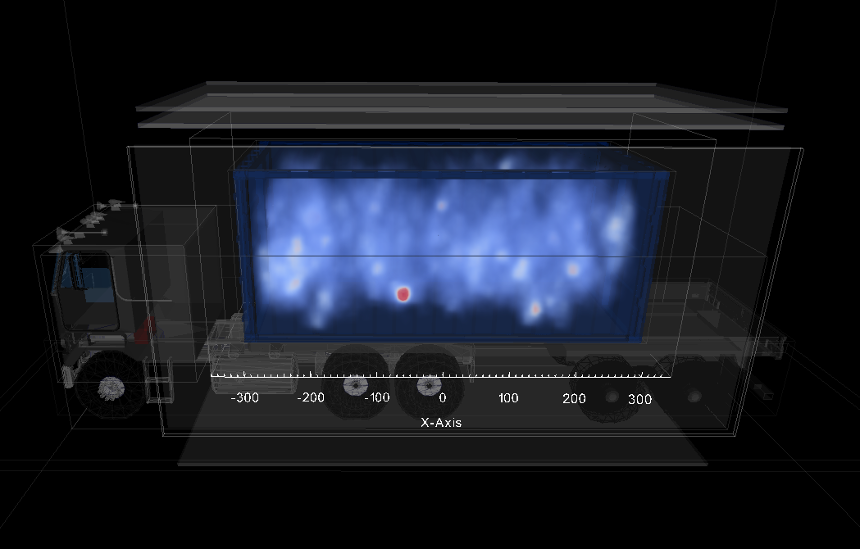

MonteCarlo: Full-Scale Truck Reconstruction: the Mu-Steel Project

Within the Mu-Steel European project we tested the feasibility to use the technique to detect shielded sources hidden in scrap metal containers headed to melting facilities. The system have to scan a full-sized container, and be on par with the industrial standard requirements, in term of exposure time, efficiency and durability. To host the entire truck, a full scale scanning portal has been simulated. A simpler and cheaper muon detector has been studied and prototyped for this application, to ensure a minor economical impact and a higher resistance to harsh environment. In Fig. 4 we show a reconstruction of a simulated truck hiding a 5 liters source inside a container filled with scrap metal.

Fig.4 – Truck filled with scrap metal hiding a shielded sources

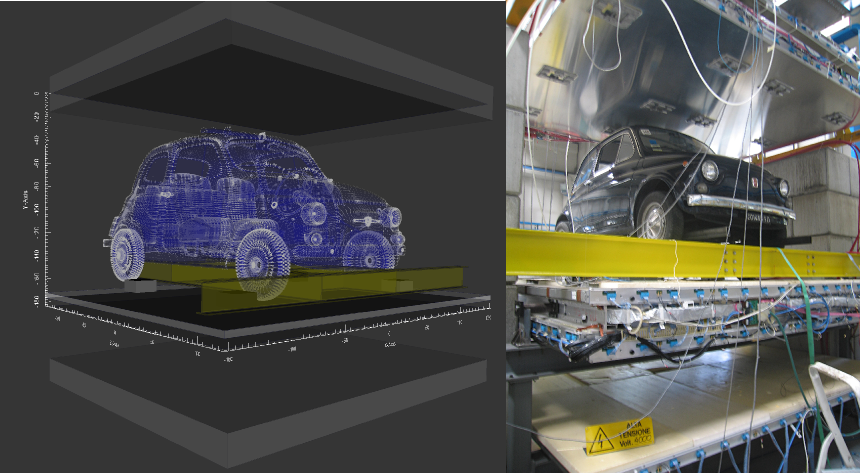

Real Data: Vehicle Reconstruction

To assure the feasibility of the scanning of a truck, we test the technique on a actual vehicle. The data are acqured inside the LNL prototype. Its size allows to scan a small, but working, vehicle: a 1967 Fiat 500! A great car, for a great purpose.

A 1967 Fiat 500 inside the muon scanner prototype at LNL

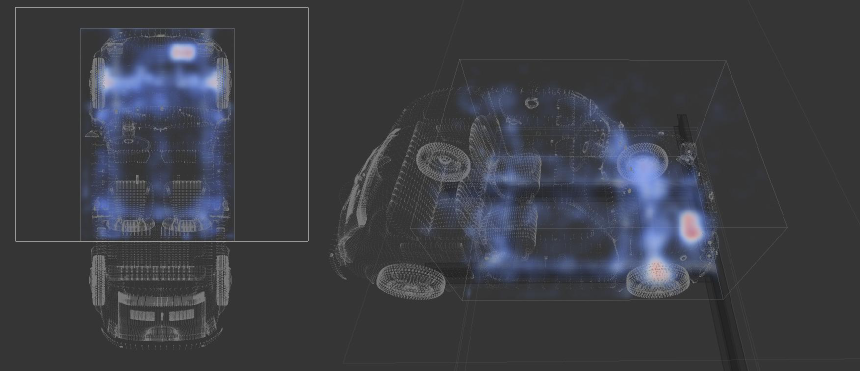

The early reconstruction of the front part of the car is shown. Note that the 1967 Fiat 500 has the trunk in the front, with the battery inside.

Front part of the reconstructed FIAT 500 – early reconstruction

Next Step: Monitoring Uranium Exaust Fuel inside the Containg Casks

A new project proposed and in study at the moment. We plan to use muon tomography to monitor the status of nuclear reactor waste inside its container without the need of exposing workers and the environment to unnecessary harm. With this passive technique, we study the possibility to measure the density distribution of depleted uranium.