Subsystem version

| Developer | Version | Release date |

|---|---|---|

2020 |

Subsystem Description

| Type | Description |

|---|---|

| Devil ethernet (Low-Level demon) | 689, 699 (Labview 2010) |

| CPU type (Low-Level demon) | Virtual Machine |

| CPU name (Low-Level demon) | vldantedev014 |

| Communication lines | Finuda Moxa Line : 192.168.192.51 (Rack 80) - (SWDAFNE2B porta 11) Kloe Moxa Line : 192.168.192.52 (Rack 77) - (SWDAFNE4B porta 21) |

Programming languages

| Language | Required Add ons/Plugings/Extensions/Libraries |

|---|---|

| LabVIEW 2010 (64-bit) - Low Level Devil | DCS environment, TML Lib (Technosoft Motion Library) |

| LabVIEW 2019 (64-bit) - High Level Interface | DCS environment |

Scrapers Dafne Layout

Hardware Layout

Hardware Front-end

The motors are controlled by drives called "MOTION SYSTEM INTERFACE DEVICE" assembled by "RAMTRON Computing".

The box is equipped with two Technosoft drives IDM240-5EI or IDM640-8EI , to operate 2 Stepper Motors

Motor description

2009/2011 series : SloSyn motor with incremental differential Encoder (400 steps/round)

2013 series : MAE motor with incremental differential Encoder HEDS 5645 (200 steps/round)

Fig. SloSyn Motor connections

Mechanical description

"Encoder" view

| CW | CCW |

|---|---|

Scraper IN | Scraper OUT |

"Bolt" view

| CW | CCW |

|---|---|

Scraper OUT | Scraper IN |

ATTENTION! All scrapers have a mechanical gearbox (20:1.5); every 20 turns of the axis the Scraper moves by 1.5 mm.

Operations on Scrapers assembly with RAMTRON drive

For relative movements the positive steps (by Technosoft Software, Manual-Controller Labview or Low-Level Devil) the Scraper must enter the chamber.

Relative movement : positive Steps → Scraper IN

DCS Window description

| Solaris Version | Linux Version |

|---|---|

| built number 20141222 | built number 20200624_rc |

New features: [ 1 ] "Ctrl On" function [ 2 ] "By Pass" function [ 3 ] "Init" procedures [ 4 ] "Bad communication" indicator |

Operative mode

Before making any movement, it is necessary to put the axis in Operational Mode using the "Oper" key .

Oper key (similarly to the magnet control); this operation allows to give current to the phases of the single motor.

It also guarantees safety on any unwanted movements once the set has been found.

"Flags for all elements" allows operation on all axes simultaneously.Two operating modes can be used without distinction. One called Absolute Movement and one called Relative Movement (optimized for fine movement).

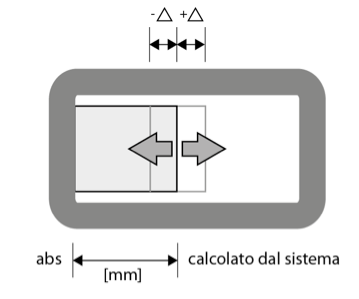

Absolute Movement

Relative Movement

Enter the value and press "IN" or "OUT" in the desired direction

Single axis homing

The "Home" button is positioned in the Advanced Display as shown in the figure.

During the Homing phase, the Scrapers performs an automatic procedure that brings it into a completely open state, followed by a reset of the relative encoder,

of the counter (Position [mm]) and of the setting field.

If the procedure is not successful, that is:

1. hourglass (clessidra) removed

2. encoder value is not zero

3. "End Run OUT" in the OFF state

the system warns with an error detectable by log.

This procedure can be repeated, unless an "overcurrent" state occurs, due to the motor malfunction.

Warning, this procedure misaligns the values written on DBFile relating to the home position of the resistive encoder (absolute),

causing a relative misalignment between the "Position" and "Absolute Position" values.

IMPORTANT! After this operation, it is recommended to report to the Control Group which will update the configuration files.

After the procedure, which takes a maximum of 2 minutes, see if the situation has been reached as shown in the figure:

Otherwise contact the Control Group.Save, load and apply configurations

To recover a configuration (it will be inserted in the Saved column [mm])

Per recuperare una configurazione (verrà inserita nella colonna Saved[mm] )

To apply the set in the Saved column [mm] to all the axes simultaneously.End-run

Scraper closed: fully inserted. | |

|---|---|

Devil Description "Dante Control System" (DCS)

The system was born to operate with scrapers that have the machine name SCHXXYYY, but the class that manages them is the MOV class,

therefore it has the following MOVXXYNY nomenclature.

Classes: MOV, SER (not implemented; see "Note") Devils : 689, 699 |

|---|

| Note: serial communication is initiated using information from the DEVIL689.system.pref e DEVIL699.system.pref file (/u2/dcs/prefs/devils/ |

DCS MOV Class

Database record

| Satic Fork | Dynamic Fork |

|---|---|

DCS Commands

| DCS Command Name | Parameters | Note | Sub-VI ref. |

|---|---|---|---|

| RESV | - | DCS System | |

| ONLN | - | DCS System | |

| BYPS | ON | OFF | DCS System | |

| PUTT | - | DCS System | |

| EMSK | - | DCS System | |

| CMSG | - | DCS System | |

| INIT | NULL | Performs the initialisation procedure | exeINIT-MOV.vi |

| RESE | NULL | Performs the reset procedure | exeRESE-MOV.vi |

AXPW | ON | OFF | Put the axis on | exeAXPW-MOV.vi |

SETS | #steps , IN | OUT | Moves the axis IN or OUT of the number of steps sent as a parameter | exeSETS-MOV.vi |

SETM | rel [mm] , IN | OUT , abs [mm] | Moves the axis IN or OUT of the millimeters sent as a parameter | exeSETM-MOV.vi |

STOP | NULL | Stops the movement | exeSTOP-MOV.vi |

HOME | NULL | Performs the homing procedure | exeHOME-MOV.vi |

SETE | encoder value [DBL] | Writes the value passed as a parameter to the relative register | exeSETE-MOV.vi |

SETC | counter value [DBL] | Writes the value passed as a parameter to the relative register | exeSETC-MOV.vi |

GENE | [String] | General purpose command | exeGENE-MOV.vi |

DCS Devil prefs

| Key | Value | Comment |

|---|---|---|

| pathFileTable | /u2/dcs/prefs/MOV/setups | at the moment present on Static DBFile |

| MOVClassNumber | 48 | DCS System Class |

| serialType | rs232 | Serial device type rs232,rs422,... |

| boudRate | 115200 | |

| serialSystemType | /dev/ttyS0 | System Resource es. ttyS0,com1,... |

| startUpAxisCicleOnOff | yes | At devil start up put all the axis ON and then OFF |

| startUpAxisOn | no | At devil start up put all the axis ON |

Technosoft IDM module programming

EasyMotion Studio is an integrated development environment for the setup and motion programming of Technosoft intelligent drives and motors.

The output of EasyMotion Studio consists of a set of setup data and a motion program, which can be downloaded to the EEPROM of your Technosoft intelligent drive / intelligent motor,

or saved onto your PC for later use.

Link for user manual : Easy Motion Studio by Technosoft

ATTENTION! Please, choose IDM240-5EI or IDM640-8EI > STEPPER > OPEN LOOP > With Incremental Encoder, in the picture below.

IDM240-5EI or IDM640-8EI

| IDM640-8EI model | IDM240-5EI and IDM640-8EI connectors layout |

Analogue and Digital I/O connections

Axis ID / Address configuration.

Cabling diagram of the Scrapers subsystem

Example from the BTF Scraper System (May 2018) for one axis only.

End Run and Emergency cabling

We used a standard to easily identify the wiring for the end-run and emergency microswitches.

| Emergency OUT | End Run OUT | Emergency IN | End Run IN |

|---|---|---|---|

| Yellow, Green | White, Grey | Red, Black | Brown, Blue |